Summary: The overall aim of the research was to facilitate the principle of “doing more with less” in terms of resources consumed in manufacturing. Novel methodologies, tools and technologies are being developed to enable radical improvements to resource efficiency.

Project Description: The principle of “doing more with less” in an increasingly resource constrained future is fundamental to sustainable development and central to the manufacturing industry’s ability to meet future demand. There is a growing realisation that increasing consumption patterns are unsustainable with a limited global material reserve and increasing demand for scarce resources is in turn not only increasing prices, but the need for radical improvements in the efficient use of materials. Existing tools and approaches to examine resource flows do not identify and support efficiency improvement options and manufacturers need support with decision making to enhance resource efficiency.

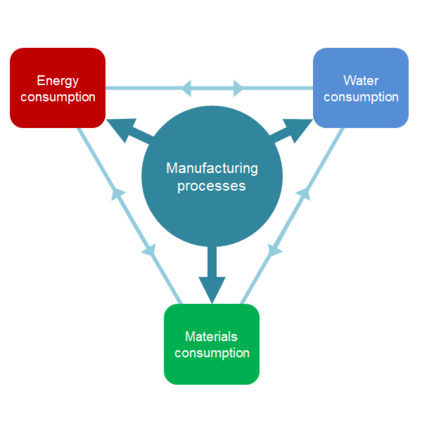

This project is investigating Resource Efficient Manufacturing (REM) and use the acquired knowledge to develop proactive methodologies, technologies and tools to support substantial resource efficiency improvements across the manufacturing sector. The research scope of this project is focused on the design of manufacturing processes and systems and how these can be made more efficient through improved measurement, modelling and management methods. The resources considered are limited to those resources that are fundamental to manufacturing and whose current and future use is most likely to have the greatest environmental impact: water, energy and materials within factory. Water and energy minimisation tools have already been developed by researchers at Loughborough’s Centre for SMART. These tools together with the new framework for material flow assessment in manufacturing systems (MFAM) and various material efficiency tools will ultimately be combined to create a single integrated ‘resource efficiency dashboard’.

The project will fully address the complexity of material flow, to assist selection and implementation of existing strategies related to product and production design. Technologies that enable accurate measurement, management and control of resources will be developed and industrial case studies will be incorporated to validate tools.

Project Highlights:

- Journal publication: A framework for material flow assessment in manufacturing systems. Gould, O., Colwill, J., 2015. A framework for material flow assessment in manufacturing systems. J. Ind. Prod. Eng. 32, 55–66. doi:10.1080/21681015.2014.1000403

- Conference publication: A material flow modelling tool for resource efficient production planning in multi-product manufacturing systems. CIRP Conference on Manufacturing Systems, 2015.