Summary: The overall aim of the research was to investigate the water usage at the process level within manufacturing applications and to facilitate water reduction through the development of a water simulation model and a water optimiser decision support tool.

Project Description: Freshwater requirement in the industrial sector is constantly increasing and is expected to double by 2030 (OECD). The supply of freshwater to such industries is severely affected by freshwater scarcity which is direct a result of over abstraction and source contamination. This situation is further aggravated by the changing climate lading to dry weather and volatility in rainfall in many arid regions. Such shortages of water along with the recent legislations have increased the cost of water and disposal of wastewater. This realisation of water scarcity and rising cost of water has forced many water intensive manufacturing industries to improve their water efficiency to reduce their manufacturing water usage. In order to improve the efficiencies through reducing water usage, a need to understand and model the water usage at the process level in manufacturing systems was identified.

A number of water modelling methodologies are currently available to model the water usage both at the product level and process level. The methodologies at the product level (e.g. Life Cycle Assessment, Water Footprinting) assess the impact of the water use in a product’s various lifecycle stages and do not provide any direction towards evaluating water efficiencies at process level. Meanwhile, the methodologies at the process level (Water Pinch Analysis) mainly focused at water minimisation through reuse and regeneration are based on reactive approaches and fail to provide a systematic analysis through which water reduction can be achieved proactively.

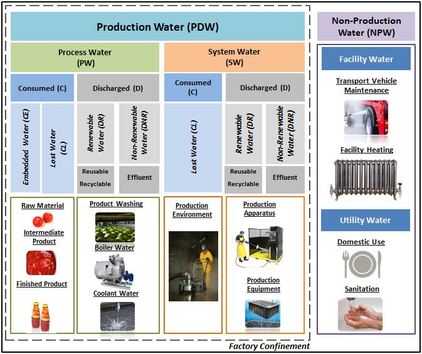

The research takes a systematic approach in modelling the water usage based on ‘where’ the water is used, ‘how’ the water is used, and the ‘type’ of water use and classifies the production water as Process Water and System Water. This level of breakdown of water assists in effectively evaluating the productivity of the water usage which aims to determine the water hotspots. A simulation modelling was used to implement the modelling framework and facilitate ‘what-if’ scenario planning. The results from the simulation model are integrated within a decision support tool to evaluate the proposed water reduction alternatives.

Project Highlights:

- Development of a framework to model the water usage at the manufacturing process level.

- Development of a methodology to evaluate the efficiency of water usage of manufacturing processes.

- Development of a water simulation model to perform ‘what-if’ scenario planning for water reduction.

- Development of a decision support tool to assess the impact of the water reduction alternatives in manufacturing processes.